Simbi yakakosha inoumbwa nemazvo kuti iite imba yekuboorera.

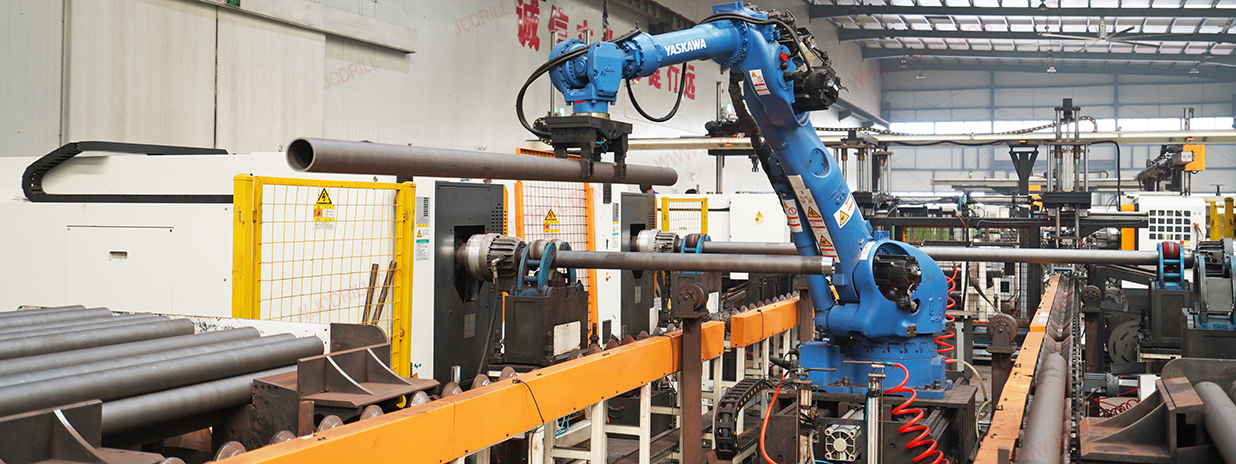

Tine seti gumi nenomwe dzeCNC machining centers dzinosanganisira 3m gantry machining center,6163 horizontal boringmachine,400 sets CNC lathes,39 sets CNC millingmachines, gumi neshanu seti yakadzika gomba rekugaya mukati,31 seti universal cylindrical grinding, uye 6-brand 2 sets 25 muchina.

Alloys anoshandisa anozivikanwa mabhizinesi emumba kutsigira, kuve nechokwadi chekuti mumabasa ekuchera dombo, kuzara kwekupfeka kwekupokana kwezvigadzirwa zvakakwirira kupfuura zviyero zveindasitiri.Kana iyo imba uye alloy ichibatanidza, isu tinoshandisa gomba rimwe, rimwe zino bvunzo, kuve nechokwadi chekuti chigadzirwa chinoshandiswa, hachioneki mazino, chinodurura chiitiko.

Nemidziyo yekupendi yakanakira, maturusi edu ese ekuchera ane kucheneswa kwepasi, kugadzirira, kupera kwekupenda, uye kukwenenzvera, pendi yemhando yepamusoro inopa maturusi ekuchera chiyero chedziviriro kubva mukunyoro uye oxidation panguva yekufambisa nekushanda.

Tinogona kuzadzisa zvinodiwa nemutengi pakunyungudutsa, kuforoma simbi yakakosha, uye simbi bhawa pamusoro pemakanikani inopenengura necenterless lathe, kuongorora ne ultrasonic chikanganiso chekuona kuti ive nechokwadi chemhando yesimbi.

Isu hatigone chete kugadzira hukuru hukuru hwekushanda asi zvakare tinokwanisa kugadzira chero zvigadzirwa zvesimbi bynormalizing, kupisa, carburizing, kudzima mafuta uye kudzima munyu, kurapwa kwepamusoro, kusviba uye nitrogen kurapwa.Isu tine ruzivo rwakapfuma uye kutonga kwakaringana pakupisa, kutonhora machining uye kurapwa kwepamusoro, kuitira kuti maworkpieces asangane nemhando yepamusoro mukushandisa.

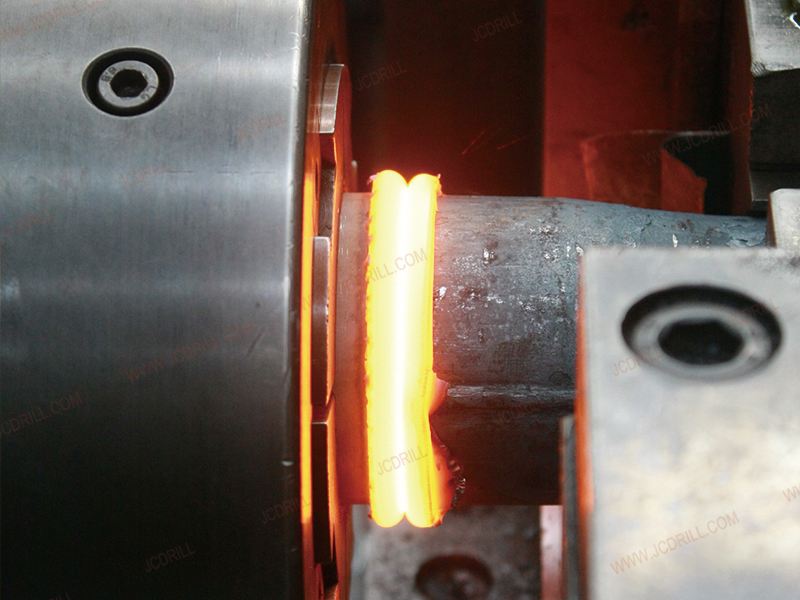

Kuti ive nechokwadi chemhando yekudhiraivha pombi welding, neinoenderera mberi friction welding tekinoroji uye makomputa kuona welding parameters.Kushandisa welding kupisa uye kumusoro deformation, iyo weld dhizaini inoiswa kune yechipiri-yechipiri kupisa kurapwa nemichina yakasimba yakakwira fre-quency quenching.Ita kuti nzvimbo yekugedhesa ive yakanaka uye yakatsvinda, uye uvandudze panzvimbo yepombi yekuchera.

Isu tinotora yakakwirira-yakasimba uye yakareruka kurongedza, iyo isingagone chete kuchengetedza kuchengetedzwa kwemidziyo yekuchera panguva yekufambisa, asi zvakare inofambisa kutakura uye kubata kwevashandisi.Zvese zvigadzirwa zvekurongedza zvinogona kugadzirwa zvinoenderana nezvinodiwa nemushandisi.